Permanent Magnetic Brakes

Permanent magnetic brakes and clutches provide “power-off” braking with excellent overload and seizing protection for all components in the drivetrain. They also provide soft starts with zero slip when a preset torque is reached. Our permanent magnetic brakes and clutches have several advantages, including:

- No electricity: no external power source, unaffected by power interruption

- No breakaway torque; zero slip when a preset torque is reached.

- Constant torque: independent of shaft (rotor) speed, at low and high speeds, the torque remains smooth and constant.

- No contacting: other than the ball bearings, there are no wearing parts.

- No friction elements: same smooth torque year after year, long life.

- No maintenance is required; there are no magnetic particles to leak or contaminate the end product.

- Operable in some of the most difficult environments.

- Brake (with shaft) and clutch (with hollow shaft) available; custom designs available

Applications / Usage

Fig. 1: As a Coupling

This is for load protection or torque limiting. The coupling-style unit is directly connected to a motor and turns at the same speed as the motor until the torque is reached. At this point, it will slip and still generate the maximum torque.

Fig. 2: As a Clutch

The unit is connected to a motor by a timing belt or gear. The housing is driven, and the shaft is the output end.

Fig. 3: As a Payout Brake

The brake is stationary, and the reel or material is fitted to the output shaft. The tension on the material will vary with the diameter.

Click here for applications and technical information regarding magnetic clutches and couplings.

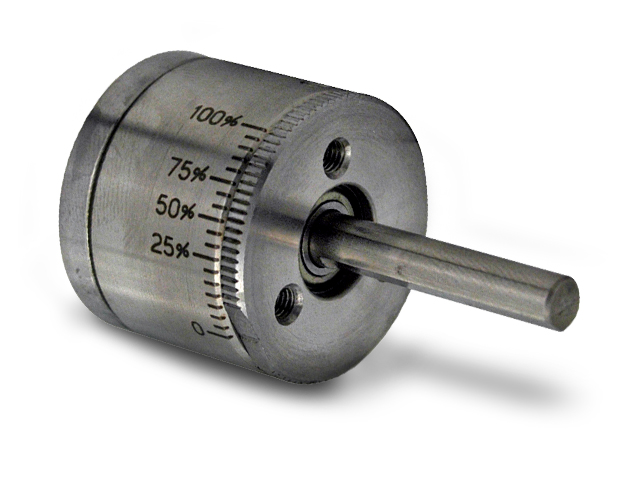

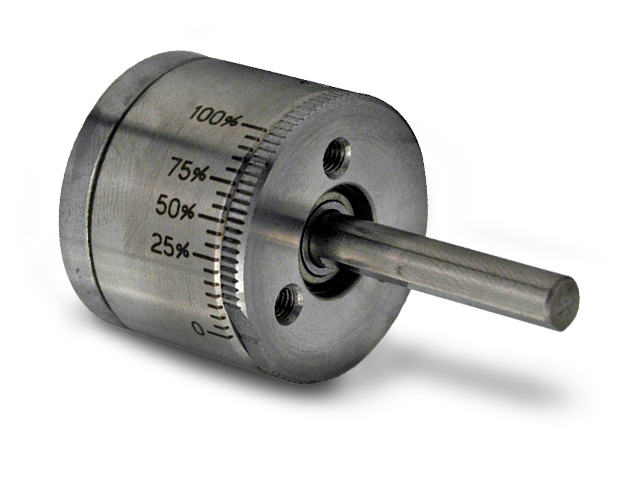

For maximum torque, all important internal clearances are ground to tolerances of less than.001 in. (0.025 mm). Magnet assemblies surround hysteresis assemblies. When like poles face each other, they produce maximum magnetic saturation of the hysteresis disc, forcing lines of flux to travel circumferentially through the hysteresis disc.

For minimum torque, when opposite poles face each other, they produce minimum saturation of the hysteresis disc. The lines of flux travel through the hysteresis disc. Combinations of adjustment angles between the two extremes give infinite adjustability. Because there are no contacting surfaces, the setting can be maintained indefinitely.