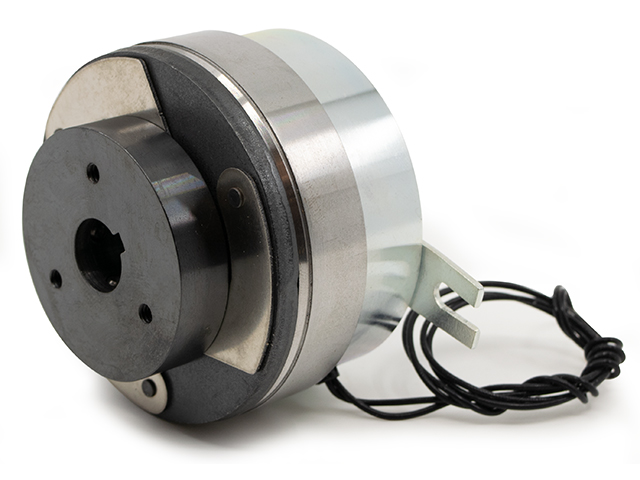

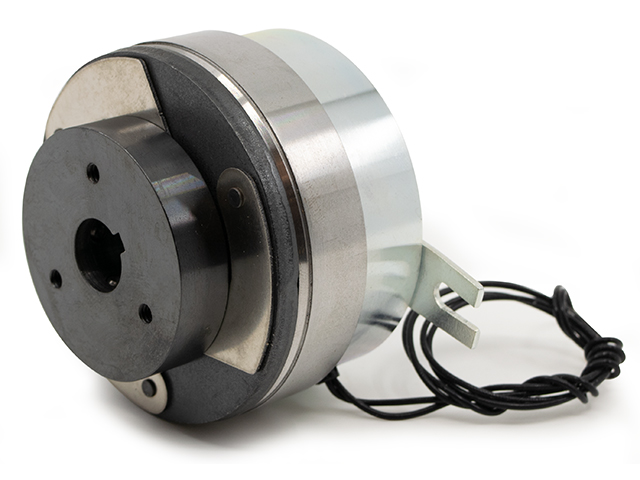

Electromagnetic, Shaft-Mounted Clutch Couplings

Electromagnetic, Shaft-Mounted Clutch Couplings

In applications for motion control, power-off brakes are frequently employed to hold or stop a load in place. The power-off brake will hold a load when power is interrupted or removed (power-off).

They are used to:

- Control unbalanced or irregular vertical loads, such as in vertical-mounted lead screws.

- Can be used to decelerate and stop torque in servo and stepper motors. Typically used for emergency stops.

There are two types of electromagnetic power-off brakes: spring-set and permanent magnets.

(Spring-set) electromagnetic power-off brakes

When the power is interrupted in the spring-set or spring-applied type, the springs apply a force to the pressure plate, which applies pressure to the friction disc holding the load on the attached component (shaft). Once power is reintroduced, the coil will attract the pressure plate, releasing the friction disc and load. Spring-set brakes can be customized using a variety of springs, friction materials, and voltages to reduce the brake’s response time. Since the unit employs spring compression to hold the load, there is some backlash that can occur.

Permanent magnet power-off brakes

Unlike spring-set brakes, permanent magnet brakes use permanent magnets to magnetically engage the armature plate and stop a load. To release the load, there is a DC coil which creates an electromagnetic field when power is applied creating an opposing force which causes the armature plate to disengage and release the load. These brakes are preferable for high-precision servo motor applications due to their ability to work at high speeds. Permanent magnetic brakes require a steady low-voltage current and therefore harsh environments with changeable temperatures are not suitable for these brakes.

SDP/SI offers both economical spring type brakes (S90SB9-series) and permanent magnetic brakes (S90MCCM series).