Ball Screws & Nuts

Ball Screws & Nuts

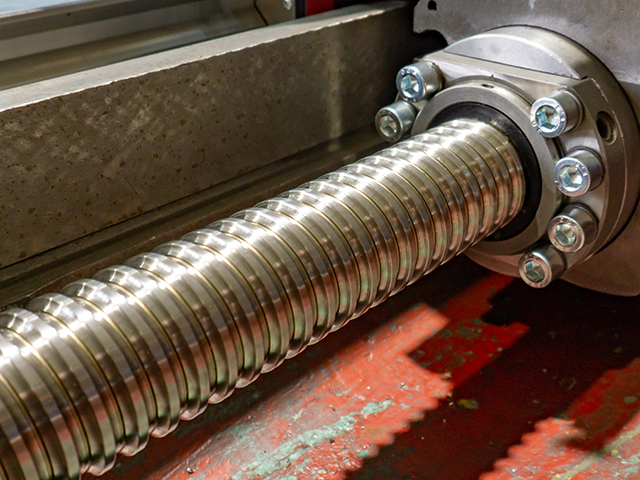

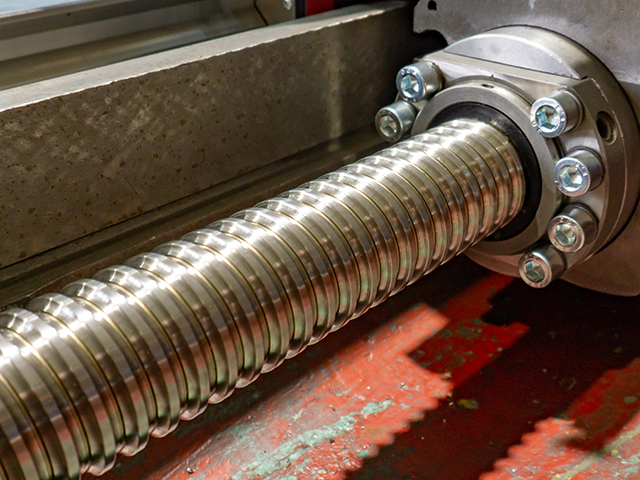

Similar to racks and pinions, ball and lead screws convert rotary motion to linear motion. A threaded shaft that serves as a screw and a ball that serves as a nut make up the assembly. The ball rotates back and forth along the threaded shaft and is made of a helical raceway packed with ball bearings.

Friction is one of the major variables influencing the effectiveness of ball and lead screws. Ball bearings are used in ball screws to minimize friction between the nut and the screws. The sliding friction present is eliminated by the rolling nature of ball screws. Matching helical grooves on ball screws and nuts enable the ball bearings to recirculate inside the nut.

To avoid back-driving, a ball screw assembly needs a braking system. For applications involving horizontal linear motion, ball screws are ideal. Due to the intricate machining required to produce ball screws, they are more expensive than lead screws and require lubrication. Ball screws are used in high-precision applications such as robotics, semiconductor manufacturing equipment, machine tools, and food processing equipment. Ball screws are available in 2.5 to 20 mm (pitches) in lengths from 452 mm to 1052 mm.